Vulcanization Molding Machine is an important equipment used for vulcanization molding of rubber and plastic materials. By applying heat and pressure, it converts unvulcanized rubber or plastic raw materials into final products with excellent physical properties. The vulcanization process not only improves the strength and wear resistance of the material, but also enhances its elasticity and heat resistance. This machine is widely used in industries such as automobiles, aviation, electronics and consumer goods to produce various vulcanized rubber parts such as tires, seals and gaskets, as well as plastic components such as gears and housings.

The significance of Vulcanization Molding Machines lies in their ability to transform raw rubber into highly functional and resilient materials, essential for the production of countless products we rely on daily. Through the careful control of heat and pressure, these machines enable the creation of rubber components that withstand wear, extreme temperatures, and challenging environments, contributing significantly to the advancement of modern industries and technology.

Model | YX-LG100T-1 |

Hot plate specification | 450*450mm |

Hot plate spacing | 250mm |

Cylinder diameter | 250mm |

Machine structure | Four column/single head/double head model |

System pressure | 18MPa |

Heating system | Imported electric heating tube |

Power supply specification | 380V/50HZ |

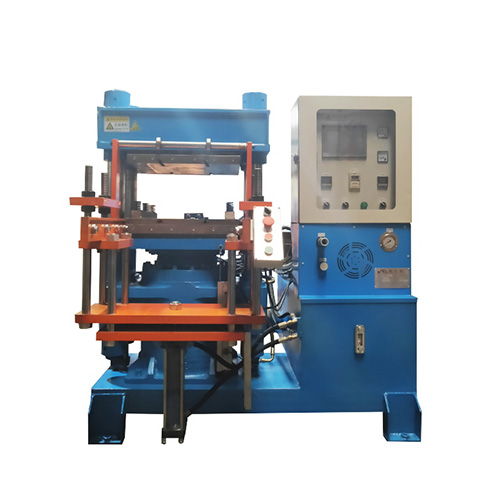

The YX-LG100T-1 Vulcanization Molding Machine is designed for efficient and precise vulcanization of rubber and plastic materials. Here’s a breakdown of its key features and specifications:

Hot Plate Specification: The machine is equipped with a substantial hot plate size of 450*450 mm, providing ample surface area for various molding applications. This size is ideal for producing large or multiple components in a single cycle.

Hot Plate Spacing: With a spacing of 250 mm between the hot plates, the machine can accommodate various mold sizes and thicknesses, ensuring versatility in production.

Cylinder Diameter: The 250 mm cylinder diameter offers robust pressure capabilities, essential for effective vulcanization and molding of materials.

Machine Structure: The YX-LG100T-1 features a four-column structure with a single head and double head configuration, enhancing stability and precision during the molding process. This setup allows for efficient handling and accurate molding.

System Pressure: Operating at a system pressure of 18 MPa, this machine provides the necessary force to ensure thorough vulcanization and optimal material properties.

Heating System: The machine uses imported electric heating tubes, ensuring reliable and efficient heating. This advanced heating system contributes to consistent temperature control and high-quality molding results.

Power Supply Specification: The machine operates on a power supply of 380V and 150Hz, suitable for industrial settings and ensuring adequate power for its operations.

Overall, the YX-LG100T-1 Vulcanization Molding Machine is designed to deliver high performance and reliability in the production of rubber and plastic components. Its advanced features and specifications make it an excellent choice for industries requiring precision and efficiency in vulcanization processes.

Essential details | |||

Place of Origin | China | Applicable Industries | Hotels, Machinery Repair Shops, Home Use |

Type | Showroom Location | None | |

Condition | New | Model | YX-LG100T-1 |

Video outgoing-inspection | Provided | Hot plate specification | 450*450mm |

Machinery Test Report | Provided | Hot plate spacing | 250mm |

Warranty of core components | 1 Year | Cylinder diameter | 250mm |

Core Components | PLC | Motor power | 4KW |

Voltage | 380V/50HZ | Temperature range | Normal temperature -350°C |

Dimension(L*W*H) | 1.8*1.7*1.65(m) | Working level | Upper and lower layer |

Warranty | 1 Year | Machine structure | Four column/single head/double head model |

Key Selling Points | Automatic | System pressure | 18MPa |

Power (kW) | 13 kW | Power | 380V/50HZ |

Weight (KG) | 1700 KG | ||

FAQ

Can vulcanization molding machines operate at different pressure levels for different applications?

Yes, these machines often feature adjustable pressure settings, allowing operators to tailor the process according to the specific rubber product being manufactured.

Yes, by adjusting the curing time, temperature, and pressure, vulcanization molding machines can produce rubber products with different hardness levels (durometers).

Yes, vulcanization molding machines must comply with international standards such as ISO (International Organization for Standardization) for safety, quality, and performance.

Hydraulic pressure is used to apply force evenly across the molds, ensuring uniform vulcanization and preventing defects in the finished rubber products.

The ease of use of a vulcanization molding machine can vary based on the specific model and its features.

Yes, some advanced vulcanization molding machines feature remote operation and digital interfaces, allowing operators to monitor and control the process from a distance.