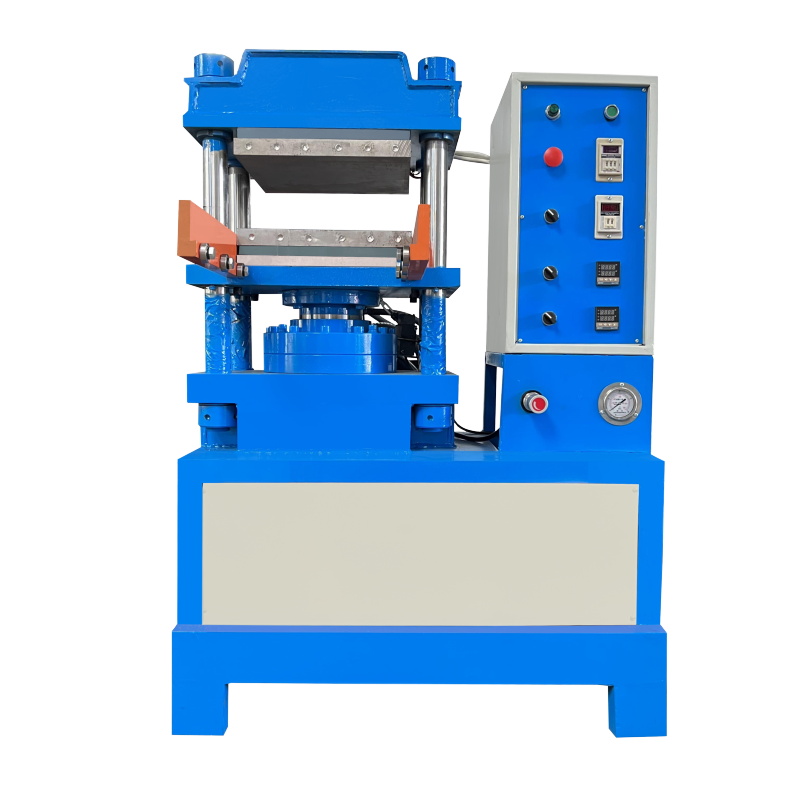

What is Rubber Vulcanization Machine?

Rubber Vulcanization Machine is a device used to vulcanize rubber materials by heating and applying pressure. The vulcanization process is an important step in rubber manufacturing. By cross-linking rubber molecules, rubber is given better physical properties such as strength, elasticity and heat resistance.

Model | YX-DJ50T |

Hot plate specification | 350*350mm |

Hot plate spacing | 150mm |

Cylinder diameter | cp150mm |

Machine structure | Four column/single head/double head model |

System pressure | 18MPa |

Heating system | Imported electric heating tube |

Power supply specification | 380V/50HZ |

Essential details | |||

Place of Origin | China | Applicable Industries | Hotels, Machinery Repair Shops, Home Use |

Type | Showroom Location | None | |

Condition | New | Model | YX-DJ50T |

Video outgoing-inspection | Provided | Hot plate specification | 350*350mm |

Machinery Test Report | Provided | Hot plate spacing | 150mm |

Warranty of core components | 1 Year | Cylinder diameter | cp150mm |

Core Components | PLC | Motor power | 3.75KW |

Voltage | 300V/50HZ | Temperature range | Normal temperature -350°C |

Dimension(L*W*H) | 1.0*1.3*1.5(m) | Working level | Upper and lower layer |

Warranty | 1 Year | Machine structure | Four column/single head/double head model |

Key Selling Points | Automatic | System pressure | 18MPa |

Power (kW) | 3.75 kW | Reducer casing | Power supply specification |

Function

Rubber processing: Improve the strength, elasticity, wear resistance and high temperature resistance of rubber through the vulcanization process, and increase its service life.

Product manufacturing: Used in the production of various rubber products such as automobile tires, seals, rubber gaskets, hoses, tapes, etc.

Improve performance: Through vulcanization, rubber has better mechanical properties and chemical stability, and adapts to more stringent working environments.

Features

High efficiency: It can be vulcanized at high temperatures to enable the rubber to quickly complete the cross-linking reaction.

Adjustable temperature and pressure: Both temperature and pressure can be adjusted to meet the production requirements of different rubber products.

Uniform heating: Advanced heating technology is used to ensure uniform heating during the vulcanization process and improve production efficiency.

Strong durability: The design is resistant to high temperature and corrosion, suitable for long-term use.

Automation control: Modern vulcanizers are equipped with PLC automatic control systems, which are simple to operate, reduce manual intervention, and ensure the stability of the production process.

Scope of use

Automotive industry: Used for the production of tires, rubber seals, gaskets, etc.

Electronics industry: Used for the vulcanization of various rubber accessories used in electronic equipment.

Aerospace: used for the production of high-performance rubber seals to adapt to extreme environmental conditions.

Household goods: manufacture rubber products in daily life, such as door mats, kitchen utensils, etc.

Construction industry: used to produce rubber products for construction such as sealing gaskets and rubber strips.

Common maintenance knowledge

Regular cleaning: The surface of the machine should be cleaned after each use to prevent rubber residue from affecting the next round of vulcanization process.

Check the heating element: ensure that the heating element is working properly to avoid uneven heating or overheating that may cause damage to the equipment.

Lubricate mechanical parts: regularly add lubricating oil to mechanical parts to ensure smooth operation of the machine and reduce wear.

Check the pressure system: ensure that the pressure of the hydraulic or pneumatic system is stable, and check the seals regularly to avoid leakage.

Calibrate the temperature sensor: regularly calibrate the temperature sensor to ensure accurate temperature during vulcanization to avoid overheating or underheating.

Electrical inspection: regularly check the electrical circuit and control system to prevent circuit failures from affecting the normal operation of the equipment.

Maintenance records: record the use and maintenance of the equipment to ensure timely maintenance and replacement of parts.

Rubber Vulcanization Machine is a device used to vulcanize rubber materials. By heating and applying pressure, the rubber has better strength, elasticity and high temperature resistance. It is widely used in the automotive, electronics, aviation and other industries. During use, regular cleaning, inspection of heating elements, lubrication of mechanical parts, etc. are the key to ensure long-term stable operation of the equipment.

FAQ

What is Rubber Vulcanization Machine?

A Rubber Vulcanization Machine is a device used to vulcanize rubber by applying heat and pressure, with the goal of increasing the strength, elasticity, heat resistance, and durability of the rubber.

What types of rubber can your vulcanizers process?

Our vulcanizers are suitable for a variety of rubbers, including natural rubber, synthetic rubber, silicone, etc.

How are the temperature and pressure of the vulcanization process controlled?

Our machines are equipped with adjustable temperature and pressure systems to ensure precise control according to the needs of different rubber products.

What is the production capacity of the equipment?

The production capacity of the equipment depends on the specific model and specifications, and can usually handle large-scale production to meet the needs of different industries.

What industries are vulcanizers suitable for?

It is mainly used in industries such as automobiles, electronics, aerospace, construction, and household goods.

Is the machine easy to operate?

Modern vulcanizers are equipped with PLC automatic control systems, which are easy to operate and can improve production efficiency.

Do you provide customized services?

Yes, we provide customized design services, which can be adjusted and optimized according to the production needs of customers.

How long does it usually take to deliver?

The delivery time for standard orders is usually 4-6 weeks, and the specific delivery time depends on the order quantity and customization requirements.

Can you provide samples?

We do not provide samples, but we can provide detailed technical parameters and operation demonstrations of the machine.

Do you support international shipping?

Yes, we support global shipping to ensure that the products are delivered to customers on time.