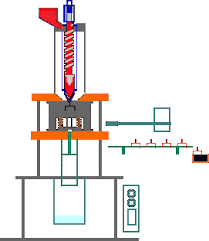

Rubber Molding Machine Price is mainly used to manufacture various rubber products, including seals, gaskets, automotive parts, medical devices and consumer products.

The equipment molds rubber materials through high temperature and high pressure to ensure that the products have precise dimensions and excellent physical properties.

Its efficient and stable production capacity meets the needs of different industries for high-quality rubber products and is an indispensable key equipment in the modern rubber processing industry.

Advantages

High-precision molding: Through precise molds and control systems, each rubber product is ensured to have consistent size and shape to meet strict quality requirements.

Efficient production: With high degree of automation and fast production speed, it can produce rubber products in large quantities and significantly improve production efficiency.

Versatility: It is suitable for a variety of rubber materials and product types, and can produce rubber products of various complex shapes and sizes.

Energy saving and environmental protection: It adopts advanced heating and pressure control technology to reduce energy consumption and waste generation, and meets environmental protection requirements.

Easy operation: Equipped with modern control systems and human-machine interfaces, it is simple to operate and easy to maintain, reducing the skill requirements for operators.

High consistency: Produced under strictly controlled temperature and pressure conditions to ensure stable and reliable product quality.

Application areas

Automotive industry: used to manufacture various automotive parts, such as seals, gaskets, shock absorbers, tires, etc.

Automotive industry: used to manufacture various automotive parts, such as seals, gaskets, shock absorbers, tires, etc.

Medical devices: produce medical-grade rubber parts, such as infusion tubes, surgical gloves, seals, etc.

Consumer electronics: manufacture rubber buttons, seals, anti-skid pads, etc. in electronic products.

Industrial manufacturing: used to produce rubber parts in various mechanical equipment, such as gaskets, seals, shock pads, etc.

Household products: produce kitchen supplies, sanitary products, anti-skid pads and other household rubber products.

Aerospace: manufacture rubber seals, shock absorbers, etc. in aircraft and spacecraft.

Precautions when using Rubber Molding Machine Price

What preparations need to be made before operation?

Make sure that the machine and the surrounding environment are clean and free of debris.

Check whether all parts of the machine are intact and confirm that there is no damage or looseness.

Check whether the power supply, air source and water source connections are normal.

Select and install appropriate molds according to production requirements, and ensure that the molds are firmly installed.

What safety precautions should be taken during operation?

Operators need to wear necessary protective equipment, such as gloves, goggles, etc.

Avoid putting your hands or other objects into the mold area to prevent pinching.

Operate in strict accordance with the operating procedures and do not change the machine settings at will.

If abnormal sounds or other abnormal conditions are found, stop the machine immediately for inspection.

How to ensure product quality?

Control the quality of raw materials to ensure that the materials meet the requirements.

Regularly calibrate and check the temperature and pressure control system of the machine to ensure that it works properly.

Produce according to the set process parameters and do not change the parameters at will.

During the production process, regularly sample products to ensure that their size and performance meet the requirements.

What precautions should be taken during maintenance and care?

Clean the machine and mold regularly to avoid residue affecting production.

Lubricate the moving parts of the machine regularly to reduce wear.

Check the electrical components and circuits to ensure that there is no aging or damage.

Perform regular inspection and maintenance according to the maintenance manual provided by the manufacturer.

What should be done if the machine fails?

Stop the machine immediately and cut off the power supply.

Record the fault phenomenon and the operation when the fault occurs.

Contact professional maintenance personnel for inspection and repair, and do not disassemble and repair the machine without authorization.

After the repair is completed, conduct a comprehensive inspection and trial run to ensure that the machine works normally before resuming production.

What basic knowledge and skills do operators need to have?

Be familiar with the structure and working principle of the machine.

Understand the basic safety operating procedures and emergency treatment measures.

Master the operation methods of the equipment and the setting of process parameters.

Be able to perform daily maintenance and simple troubleshooting.

By following these precautions, you can ensure the safe and efficient operation of the Rubber Molding Machine Price while ensuring the production of high-quality rubber products.