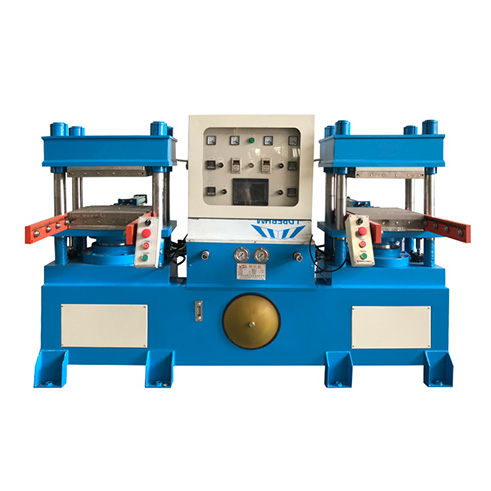

The Vulcanized Rubber Mold Machine, also known as a Vulcanizing Press, finds application across various industries for the production of rubber products

Model | YX-DJ63T-2H |

Hot plate specification | 400*400mm |

Hot plate spacing | 200mm |

Cylinder diameter | 200mm |

Machine structure | Four column/single head/double head model |

System pressure | 18MPa |

Heating system | Imported electric heating tube |

Power supply specification | 380V/50HZ |

Here are some key applications of the Vulcanized Rubber Mold Machine:

Automotive Industry: In the automotive sector, Vulcanized Rubber Mold Machines are used to manufacture various rubber components such as seals, gaskets, hoses, and vibration isolators. These components are crucial for ensuring the proper functioning of vehicles and are used in engines, transmissions, suspension systems, and other critical areas.

Electronics Industry: Vulcanized Rubber Mold Machines are utilized in the electronics industry for producing rubber components used in electronic devices and appliances. These components include rubber seals, gaskets, and insulating materials that provide protection against moisture, dust, and electrical interference.

Construction Industry: In the construction sector, Vulcanized Rubber Mold Machines are employed to fabricate rubber products for building infrastructure and structures. Rubber gaskets, seals, and expansion joints are used in construction applications to provide waterproofing, thermal insulation, and structural flexibility.

Medical Industry: Vulcanized Rubber Mold Machines play a vital role in the medical industry for manufacturing various rubber components used in medical devices and equipment. These components include seals, gaskets, tubing, and grips for surgical instruments and medical devices, as well as components for prosthetics and orthopedic devices.

Aerospace Industry: The aerospace sector relies on Vulcanized Rubber Mold Machines to produce rubber components for aircraft and spacecraft. Rubber seals, gaskets, O-rings, and vibration dampers are used in aerospace applications to ensure air and fluid-tight seals, as well as to mitigate vibrations and shocks.

Consumer Goods: Vulcanized Rubber Mold Machines are used in the production of consumer goods such as footwear, sporting goods, toys, and household products. Rubber components such as shoe soles, grips, balls, and seals are manufactured using these machines to meet the diverse needs of consumers.

Mining and Industrial Equipment: In the mining and industrial sectors, Vulcanized Rubber Mold Machines are employed to fabricate rubber components used in heavy machinery, equipment, and conveyor systems. Rubber linings, seals, and belts are essential for protecting equipment from wear, abrasion, and corrosion in harsh operating environments.

Oil and Gas Industry: Vulcanized Rubber Mold Machines are utilized in the oil and gas sector for producing rubber components used in drilling equipment, pipelines, and offshore platforms. Rubber seals, gaskets, and packers are critical for maintaining the integrity of oil and gas installations and preventing leaks and environmental contamination.

Marine Industry: In the marine sector, Vulcanized Rubber Mold Machines are used to manufacture rubber components for boats, ships, and marine equipment. Rubber seals, gaskets, O-rings, and fenders are essential for ensuring watertight seals, vibration isolation, and impact resistance in marine applications.

Customized Products: Vulcanized Rubber Mold Machines are also used by manufacturers and businesses to produce customized rubber products for specific applications. These may include specialty seals, gaskets, and components tailored to meet the unique requirements of customers in various industries.

In summary, the Vulcanized Rubber Mold Machines plays a crucial role in the production of rubber products across a wide range of industries, including automotive, electronics, construction, medical, aerospace, consumer goods, mining, oil and gas, marine, and customized manufacturing. Its versatility and ability to manufacture high-quality rubber components make it indispensable in modern manufacturing processes.