In a groundbreaking stride towards innovation in industrial processes, Electric Vulcanizing Machines have emerged as the vanguards of modern rubber processing, reshaping the landscape of manufacturing. Celebrating their role as catalysts for efficiency, precision, and quality, these machines are garnering widespread attention across diverse industries.

Unveiling the Power of Electric Vulcanization

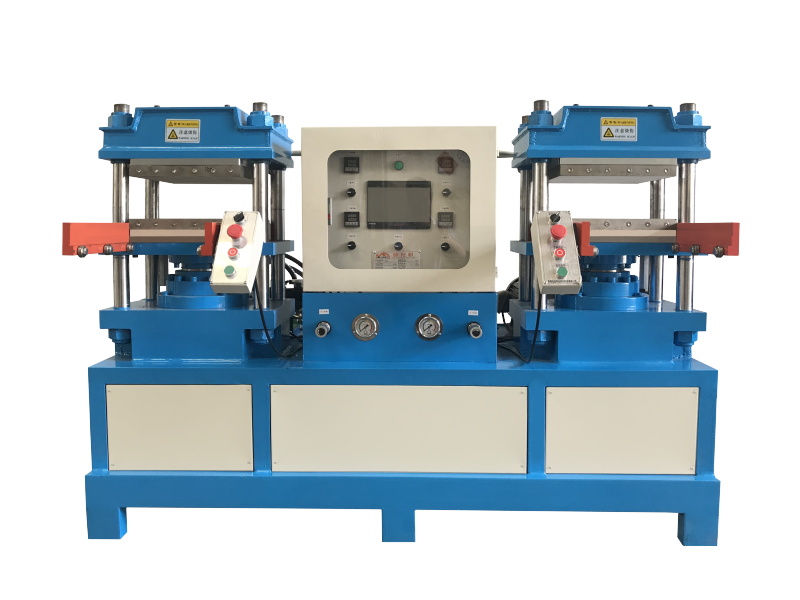

The Electric Vulcanizing Machine, a marvel of engineering, is taking the world of rubber processing by storm. Gone are the days of traditional vulcanization methods; this sophisticated apparatus harnesses controlled heat with unparalleled precision to elevate the properties of rubber and elastomeric materials. It stands as a testament to the relentless pursuit of excellence in manufacturing.

Efficiency Redefined

One of the standout features of Electric Vulcanizing Machines lies in their exceptional efficiency. By optimizing energy consumption and minimizing downtime, these machines have become indispensable in industries where every moment counts. The swift heating and cooling capabilities ensure a seamless production flow, enhancing overall operational efficiency.

Precision at Its Core

At the heart of the electric vulcanization process is precise temperature control. This key feature guarantees uniform curing, resulting in rubber products with enhanced tensile strength, resilience, and longevity. Industries relying on rubber components, such as automotive manufacturing and conveyor systems, now benefit from a level of precision that was once considered unattainable.

Versatility Tailored to Industry Needs

Electric Vulcanizing Machines showcase remarkable versatility, adapting seamlessly to diverse manufacturing requirements. Whether in the creation of conveyor belts for mining, automotive components for cutting-edge vehicles, or industrial hoses for complex machinery, these machines prove that innovation can be tailored to meet the unique demands of each industry.

A Safety Net for Industrial Applications

In the pursuit of progress, safety remains paramount. Electric Vulcanizing Machines prioritize this with advanced safety features. Temperature sensors, emergency shut-off mechanisms, and user-friendly interfaces collectively contribute to a secure working environment, ensuring that the manufacturing process is not just efficient but also safe.

Industries Embrace the Transformation

From conveyor belt manufacturing to automotive production, the influence of Electric Vulcanizing Machines is felt far and wide. These machines have become integral to the creation of durable rubber components, impacting industries ranging from medical devices to aerospace applications. The rubber processing landscape is undergoing a transformative shift, with these machines at the forefront of change.

Future Outlook: Where Innovation Meets Imagination

As Electric Vulcanizing Machines celebrate their prominence in the industrial realm, the future holds even more promise. Continued innovation and adaptation to emerging technologies are on the horizon, promising a dynamic landscape where rubber processing reaches new heights of efficiency and quality.

In conclusion, the Electric Vulcanizing Machine's first year in the spotlight is a testament to its transformative impact on rubber processing. As industries continue to evolve, these machines stand as beacons of progress, heralding a new era where precision, efficiency, and versatility converge to redefine the standards of manufacturing excellence.