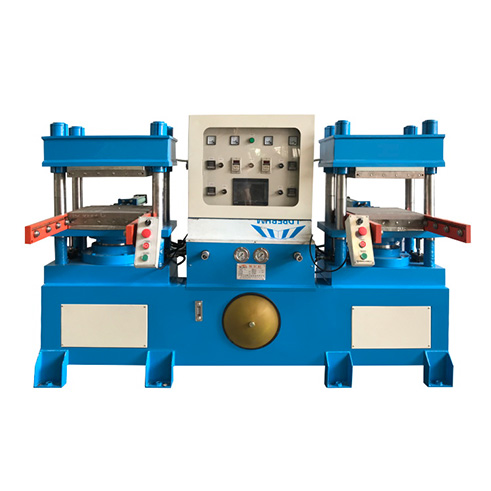

Vulcanized Rubber Mold Machine is an industrial equipment specially used for heating and molding rubber products. With the synergistic effect of high temperature and high pressure, the raw rubber is vulcanized to form rubber products with established strength, elasticity, wear resistance and stability. The equipment strictly controls the temperature, time and pressure during the production process to ensure the consistency of product performance. It is widely used in automobile, medical, industrial, home appliances, electronics and other industries.

Model | YX-DJ63T-2H |

Hot plate specification | 400*400mm |

Hot plate spacing | 200mm |

Cylinder diameter | 200mm |

Machine structure | Four column/single head/double head model |

System pressure | 18MPa |

Heating system | Imported electric heating tube |

Power supply specification | 380V/50HZ |

Essential details | |||

Place of Origin | China | Applicable Industries | Hotels, Machinery Repair Shops, Home Use |

Type | Showroom Location | None | |

Condition | New | Model | YX-DJ63T-2H |

Video outgoing-inspection | Provided | Hot plate specification | 400*400mm |

Machinery Test Report | Provided | Hot plate spacing | 200mm |

Warranty of core components | 1 Year | Cylinder diameter | 200mm |

Core Components | PLC | Motor power | 4KW |

Voltage | 300V/50HZ | Temperature range | Normal temperature -350°C |

Dimension(L*W*H) | 2.6*1.4*1.6(m) | Working level | Upper and lower layer |

Warranty | 1 Year | Machine structure | Four column/single head/double head model |

Key Selling Points | Automatic | System pressure | 18MPa |

Power (kW) | 4 kW | Power | 380V/50HZ |

Weight (KG) | 2600 KG | ||

Material:

Main frame of the equipment: Made of high-strength steel or cast steel, it has good mechanical strength and deformation resistance.

Mold material: Mainly alloy steel or heat-treated steel, with excellent thermal conductivity, high temperature resistance and corrosion resistance.

Hot press plate: High-strength thermal conductive alloy material or stainless steel is used, and the surface is hardened to ensure uniform temperature conduction.

Hydraulic system: The hydraulic cylinder body is made of wear-resistant alloy steel, the sealing ring is high-performance oil-resistant rubber, and the pipeline is made of industrial-grade high-pressure hose.

Electrical control system: The shell is made of aluminum alloy or cold-rolled steel plate, and the internal circuit components meet industrial standards to meet the needs of continuous and stable operation.

Uses:

Automobile industry: used to manufacture automobile oil seals, shock-absorbing pads, sealing rings, foot pads, rubber dust covers, etc.

Electronic and electrical industry: used to produce conductive rubber parts, shock-absorbing gaskets, cable sealing heads, switch rubber buttons, etc.

Medical industry: production of silicone rubber syringe pistons, seals, catheter joints, hemostatic rings, etc.

Machinery and equipment industry: processing industrial seals, O-rings, rubber pads, non-slip foot pads, etc.

Home appliances and daily necessities industry: production of silicone molds, rubber handles, remote control buttons, kitchen utensils and other life products.

Features:

The efficient vulcanization system supports hot pressing vulcanization of various rubber materials, such as natural rubber, nitrile rubber, silicone rubber, fluororubber, etc.

The mold can be customized as a single-layer, multi-layer, upper and lower mold structure to improve production flexibility

Precision temperature control system, temperature difference control accuracy can reach ±1℃.

The hydraulic system is stable, the output is balanced, and it is suitable for long-term high-pressure operation.

The control system adopts PLC automatic control to realize automatic management of temperature, time and pressure.

A variety of operation modes are available, and manual, semi-automatic and fully automatic switching is convenient.

It has auxiliary functions such as automatic ejection, mold separation, rapid heating, and automatic preheating.

The frame is sturdy, the structure is compact, and the footprint is small, which is convenient for layout and transportation.

Optional mold cooling system can improve production efficiency and shorten the molding cycle.

Advantages:

Improve the qualified rate of products, high dimensional accuracy, smooth edges without flash

Save human resources, high level of automation, suitable for 24-hour continuous operation

Fast production cycle, short vulcanization time, suitable for large-scale and high-frequency order production

Strong molding pressure, can ensure the molding effect of large and complex rubber parts

Strong mold compatibility, suitable for various types of rubber products and customized specifications

Simple operation interface, easy training and on-the-job training, convenient maintenance

Reasonable energy consumption control, stable equipment operation, and reduced long-term use costs

Can be connected to assembly lines or robot systems to achieve unmanned operation

Long service life, the main structural material is corrosion-resistant and fatigue-resistant, ensuring long-term operation

Improve the overall mechanical properties of molded rubber parts, such as elasticity, wear resistance, and aging resistance

FAQ:

Can the equipment adapt to different types of rubber materials?

Yes, Vulcanized Rubber Mold Machine supports a variety of rubber materials such as natural rubber, nitrile rubber, EPDM, silicone rubber, fluororubber, etc. Users only need to set the corresponding temperature, pressure and vulcanization time parameters according to different materials.

Is the mold temperature uniform during operation?

The equipment is equipped with a multi-point temperature control module and a high thermal conductivity heating plate to ensure uniform temperature distribution throughout the mold, avoid local overheating or insufficient vulcanization, and improve product consistency and quality stability.

Is it convenient to replace the mold?

The equipment is generally designed with a quick-install mold fixture system, and the mold platform has high positioning accuracy, which makes mold replacement quick and convenient, with an average replacement time of less than 10 minutes, effectively improving production efficiency.

Is it suitable for mass production?

Very suitable, the equipment supports multi-mode structure, stackable mold design and automated control, can achieve high-efficiency vulcanization operations, and is an ideal choice for industrial mass production.

Is the daily maintenance of the equipment complicated?

The maintenance is relatively simple, mainly including hydraulic oil replacement, heating plate surface cleaning, regular inspection of electronic control circuits, and aging detection of sealing rings. Manufacturers usually provide detailed maintenance manuals and training instructions to facilitate operators to get started.