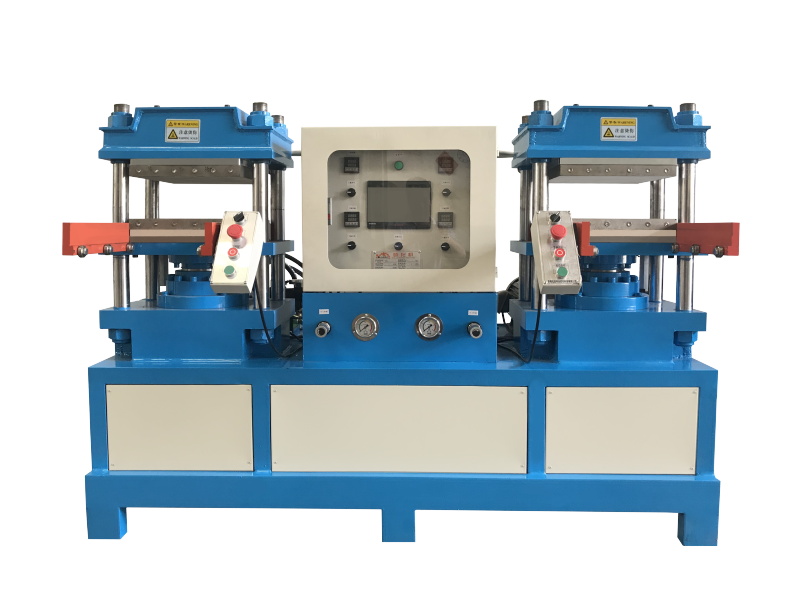

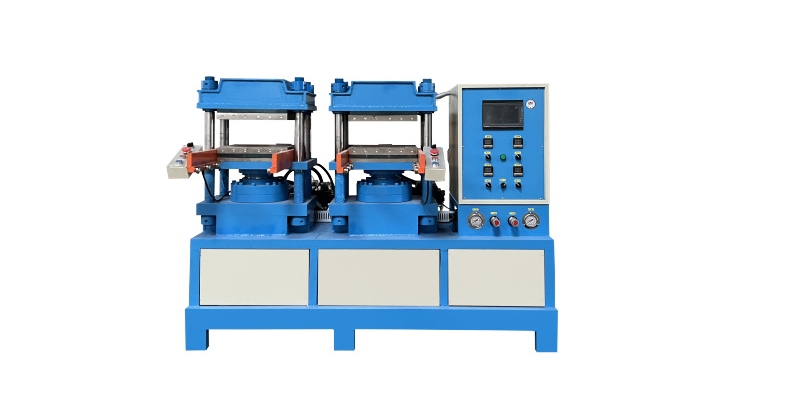

An Electric Vulcanizing Machine is a piece of equipment used in the rubber industry to cure or vulcanize rubber products. Vulcanization is a process in which rubber is treated with heat and additives to improve its strength, elasticity, and other properties. Electric Vulcanizing Machines provide controlled heating to achieve the necessary curing conditions for various rubber products. Electric Vulcanizing Machines consist of a heated platen or plate that applies heat and pressure to the rubber material. The rubber product, often in the form of sheets, profiles, or molds, is placed between the heated platens. The machine then heats the rubber to a specific temperature, allowing chemical reactions to occur that cross-link the rubber molecules and create the desired material properties. Some electric vulcanizing machines are equipped with automation features, such as programmable controls, timers, and alarms, which simplify the vulcanization process and reduce human intervention. Compared to older methods, electric vulcanizing machines can be more energy-efficient, contributing to cost savings and environmental considerations.

Model | YX-DJ50T |

Hot plate specification | 350*350mm |

Hot plate spacing | 150mm |

Cylinder diameter | 150mm |

Machine structure | Four column/single head/double head model |

System pressure | 18MPa |

Heating system | Imported electric heating tube |

Power supply specification | 380V/50HZ |

Essential details | |||

Place of Origin | China | Applicable Industries | Hotels, Machinery Repair Shops, Home Use |

Type | Showroom Location | None | |

Condition | New | Model | YX-DJ50T |

Video outgoing-inspection | Provided | Hot plate specification | 350*350mm |

Machinery Test Report | Provided | Hot plate spacing | 150mm |

Warranty of core components | 1 Year | Cylinder diameter | 150mm |

Core Components | PLC | Motor power | 3.75KW |

Voltage | 300V/50HZ | Temperature range | Normal temperature -350°C |

Dimension(L*W*H) | 1.4*2.2*1.5(m) | Working level | Upper and lower layer |

Warranty | 1 Year | Machine structure | Four column/single head/double head model |

Key Selling Points | Automatic | System pressure | 18MPa |

Power (kW) | 3.75 kW | Reducer casing | Power supply specification |

Weight (KG) | 2000 KG | ||

The Electric Vulcanizing Machine stands as a testament to advancements in industrial technology, offering a range of advantages and finding applications in diverse fields. Below, we explore the key benefits of this machine and its various application domains.

Efficient Vulcanization Process:

The Electric Vulcanizing Machine excels in providing an efficient vulcanization process for rubber and elastomeric materials. Vulcanization enhances the durability, strength, and elasticity of rubber, making it suitable for various applications.

Precise Temperature Control:

One of the key advantages lies in its ability to maintain precise temperature control during the vulcanization process. This ensures optimal curing conditions, preventing under or over-vulcanization and resulting in high-quality rubber products.

Reduced Downtime:

Quick heating and cooling capabilities minimize downtime, increasing overall operational efficiency. This is particularly advantageous in industries where production continuity is crucial.

Safety Features:

Modern electric vulcanizing machines often come equipped with advanced safety features, including temperature sensors, emergency shut-off mechanisms, and user-friendly controls, ensuring a secure working environment.

Conveyor Belt Manufacturing:

Electric Vulcanizing Machines play a pivotal role in the production of conveyor belts. Vulcanized belts exhibit enhanced strength, durability, and resistance to wear and tear, making them ideal for industries such as mining, logistics, and manufacturing.

Automotive Industry:

Rubber components in the automotive sector, such as seals, gaskets, and O-rings, undergo vulcanization using electric vulcanizing machines. This ensures that these components meet the stringent quality and performance standards of the automotive industry.

Rubber Product Manufacturing:

From industrial hoses to seals used in construction equipment, electric vulcanizing machines are employed in the manufacturing of a wide array of rubber products, ensuring their longevity and reliability.

In conclusion, the Electric Vulcanizing Machine stands as a cornerstone in industries relying on vulcanized rubber products, providing efficiency, reliability, and versatility across various manufacturing processes. Its advantages make it an indispensable tool for enhancing the properties of rubber materials in diverse applications.

Modern Vulcanizing Equipment

Modern vulcanizing equipment has evolved to incorporate advanced technologies and features that enhance efficiency, accuracy, safety, and control in the rubber curing process. Modern vulcanizing equipment often features precise temperature control systems that maintain consistent curing temperatures. This is crucial for achieving optimal curing results and product quality. PLCs and advanced control systems allow operators to program and automate the vulcanization process. This improves repeatability, reduces human error, and enhances productivity. Many modern vulcanizing machines come equipped with data logging capabilities that record curing parameters and performance. This data can be used for quality control and analysis. Modern equipment is designed to ensure uniform heat distribution across the rubber material being cured. This eliminates hot spots and ensures consistent curing results. Energy-efficient heating elements and insulation materials are often used to reduce energy consumption and operational costs.

Vulcanizing Machine Price

The price of a vulcanizing machine can vary significantly based on various factors, including the machine's size, capacity, features, brand reputation, technical specifications, automation level, and the manufacturer's location. Additionally, market demand and economic conditions can also influence pricing. For smaller, basic models, prices can start from a few thousand dollars. More advanced models with larger capacities, automation features, and higher precision temperature control can range from tens of thousands to even hundreds of thousands of dollars or more. In order to get an accurate quotation, you can contact us, we can provide you with the latest pricing information according to your specific requirements.

Vulcanizing Press for Sale

Vulcanizing presses are essential equipment in industries that work with rubber and other elastomers. These machines play a crucial role in the vulcanization process, which involves subjecting rubber materials to heat and pressure to improve their strength, elasticity, and durability. Investing in a vulcanizing press is a significant decision that can impact your production processes and product quality. By understanding the features, applications, and considerations involved, you can make an informed choice that aligns with your business needs and goals. Consulting with reputable manufacturers and suppliers will help you find the right vulcanizing press for sale that meets your requirements and contributes to your operational success. Vulcanizing presses come in various configurations, such as hydraulic, mechanical, and electric. Each type has its advantages, with hydraulic presses offering high force capabilities, mechanical presses suitable for simple applications, and electric presses providing precision and control. The platen size determines the maximum size of the rubber products that can be processed. Vulcanizing presses may have single or multiple platens, allowing for multiple products to be cured simultaneously. Choose a manufacturer that offers comprehensive technical support, training, and after-sales service. Look for manufacturers that can provide customization options to meet your specific needs and rubber formulations.

Electric Vulcanizing Machines offer several advantages over traditional vulcanization methods. These include improved energy efficiency, precise temperature regulation, reduced downtime, and enhanced safety features. The transition to electric systems is driven by the need for consistent and high-quality vulcanization results while optimizing resource utilization.

The electric vulcanization process significantly improves the quality of rubber products. It ensures uniform curing, resulting in rubber materials with enhanced tensile strength, resilience, and resistance to wear and tear. This improved quality is particularly crucial in industries where reliable and durable rubber components are essential, such as automotive manufacturing and conveyor systems.

Yes, Electric Vulcanizing Machines are highly versatile and can be customized to suit various applications. Whether it's conveyor belts, automotive components, industrial hoses, or footwear soles, these machines can adapt to the specific vulcanization requirements of different industries. Their flexibility makes them indispensable in diverse manufacturing settings.

Electric Vulcanizing Machines contribute significantly to product safety by providing precise and controlled vulcanization processes. The incorporation of safety features, such as temperature monitoring and emergency shut-off mechanisms, ensures that the vulcanization process is carried out securely. This is particularly crucial in industries like aerospace and medical, where product safety standards are paramount.