What is Portable Conveyor Belt Vulcanizing Machine 2025

Definition: The equipment uses a heating plate, a pressure system (usually water pressure or hydraulic pressure) and a rapid cooling system to perform hot vulcanization treatment on the joint part of the conveyor belt to achieve a firm fusion of the new and old rubber layers.

Portable design: The overall structure is lightweight and mostly made of high-strength aluminum alloy materials, which is convenient for on-site movement and operation.

Heavy industries rely on robust materials to maintain operations. Rubber components produced using vulcanization equipment, including conveyor belts and power transmission belts, ensure uninterrupted manufacturing processes even under extreme conditions. This equipment contributes to the efficient functioning of industries ranging from mining to manufacturing, underpinning industrial progress.

Product Specifications

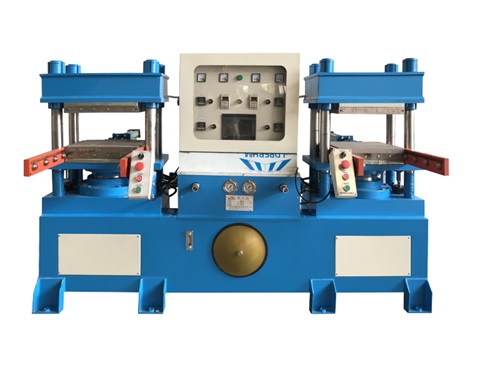

Model | YX-DJ63T-2H |

Hot plate specification | 400*400mm |

Hot plate spacing | 200mm |

Cylinder diameter | 200mm |

Machine structure | Four column/single head/double head model |

System pressure | 18MPa |

Heating system | Imported electric heating tube |

Power supply specification | 380V/50HZ |

Essential details | |||

Place of Origin | China | Applicable Industries | Hotels, Machinery Repair Shops, Home Use |

Type | Showroom Location | None | |

Condition | New | Model | YX-DJ63T-2H |

Video outgoing-inspection | Provided | Hot plate specification | 400*400mm |

Machinery Test Report | Provided | Hot plate spacing | 200mm |

Warranty of core components | 1 Year | Cylinder diameter | 200mm |

Core Components | PLC | Motor power | 4KW |

Voltage | 300V/50HZ | Temperature range | Normal temperature -350°C |

Dimension(L*W*H) | 2.6*1.4*1.6(m) | Working level | Upper and lower layer |

Warranty | 1 Year | Machine structure | Four column/single head/double head model |

Key Selling Points | Automatic | System pressure | 18MPa |

Power (kW) | 4 kW | Power | 380V/50HZ |

Weight (KG) | 2600 KG | ||

Features and Advantages

Fast heating and cooling: It can reach the vulcanization temperature within 25 to 30 minutes, and quickly cool down with the help of water cooling or air cooling system to improve operating efficiency.

Precise control: Built-in digital display and intelligent control system to ensure uniform and stable temperature and pressure, and high vulcanization quality.

Energy saving and environmental protection: Low energy consumption, high thermal efficiency, reduce operating costs, and meet green production requirements.

Easy operation: High degree of automation, suitable for on-site repair and splicing of various conveyor belt materials (such as rubber, PU, PVC, etc.).

Core application areas and applications

Mining and metallurgy: Used for on-site repair of conveyor belts in mines and smelters to reduce the risk of downtime.

Building materials and cement industry: Widely used in cement plants and building materials production lines to ensure continuous production.

Ports, logistics and energy: Suitable for conveyor belt maintenance in docks, ports, power plants and other occasions to ensure stable operation of equipment.

On-site emergency repair: The portable design makes it shine in remote areas or emergency repair occasions, and quickly resumes production.

Maintenance points

Daily cleaning: Thoroughly clean the vulcanizer and related parts after each operation to prevent rubber residue from affecting equipment performance.

Regular calibration: Check the heating plate, pressure sensor and digital control system to ensure accurate temperature and pressure data.

Lubrication and inspection: Regularly lubricate mechanical connection parts and transmission systems, and replace worn parts in time.

Intelligent monitoring upgrade:

Integrate Internet of Things (IoT) sensors to achieve real-time monitoring of key parameters (such as temperature, pressure, and vibration).

Adopt remote diagnosis and early warning systems to achieve fault prediction and online maintenance to reduce downtime.

Update firmware and software regularly to improve system security and ease of operation to meet more efficient, energy-saving, and environmentally friendly production requirements.

FAQ

What should I do if the temperature of the equipment rises slowly or fails to reach the set temperature during heating?

Possible reasons:

Heating plate or temperature control system failure

Insufficient power supply voltage

Incorrect setting of thermostat parameters

Solution:

Check whether the heating plate is damaged, if damaged, replace it

Ensure that the power supply voltage is stable and meets the equipment requirements

Recheck the thermostat setting value and adjust it to the correct parameter

The temperature is too high during the heating process, resulting in a decrease in the quality of the bonding. How to deal with it?

Possible reasons:

Thermostat failure or set temperature is too high

Temperature sensor failure

Solution:

Adjust the thermostat setting temperature to avoid overheating

Replace the temperature sensor to ensure accurate temperature measurement

The water cooling system cannot work properly, affecting the cooling speed. How to solve it?

Possible reasons:

Water pipe blockage or leakage

Water pump failure

Solution:

Check whether the water pipe is unobstructed, if there is a blockage, clean it in time

Ensure that the water pump is working properly, if damaged, replace it

Insufficient pressure leads to poor vulcanization effect, how to troubleshoot?

Possible causes:

Leakage in hydraulic system or air pressure system

Pressure pump failure

Solution:

Check whether the hydraulic pipeline has leakage, and replace it in time if it is damaged

Ensure that the pressure pump is operating normally, and repair or replace it if necessary

What should I do if bubbles appear in the vulcanized joint or the bonding is not strong?

Possible causes:

Insufficient vulcanization temperature or pressure

Uncleaned bonding surface

Glue quality problem

Solution:

Ensure that the vulcanization temperature and pressure meet the process requirements

Thoroughly clean the joint surface to remove impurities and oil stains

Use high-quality vulcanized glue and operate according to standards

How to deal with excessive current during equipment use?

Possible causes:

Aging or short circuit of power line

Internal circuit failure of heating plate

Solution:

Check the power line to ensure that the line is normal

Test the resistance value of the heating plate and replace it in time if abnormality is found

What should I do if the power is suddenly cut off during the operation of the vulcanizer?

Possible causes:

Unstable power supply

Equipment overload causes protection device to start

Solution:

Check whether the power supply is normal, and restart the device after power is restored

Ensure that the equipment load is within the rated range to avoid overload operation

These are common problems and solutions during the use of Portable Conveyor Belt Vulcanizing Machine. If you have other specific questions, please feel free to consult in detail!