The Two Roll Rubber Mill is a crucial piece of machinery in the rubber industry, commonly used for mixing, refining, and processing rubber materials. Whether you're involved in rubber manufacturing, product development, or quality control, understanding the functionality and features of a Two Roll Mill Machine is essential to improving production efficiency and quality.

What is a Two Roll Rubber Mill?

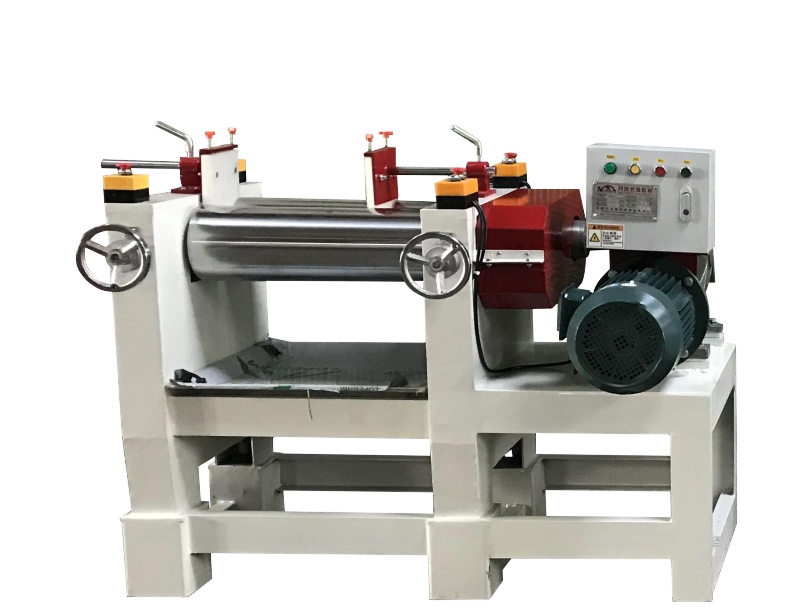

A Two Roll Rubber Mill Machine consists of two heavy rollers that rotate in opposite directions, exerting shear forces on the rubber. These mills are used to mix rubber compounds, make rubber sheets, and adjust the viscosity and consistency of the rubber. The machine is primarily employed in the production of various rubber products, including tires, belts, gaskets, and more.

The two rollers come in various sizes, with the most common being between 6 inches and 14 inches in diameter. These mills can handle large volumes of rubber, making them ideal for industrial-scale production.

Model | YX-GK180 |

Diameter of Roll(mm) | 190mm |

Length of Roll(mm) | 550mm |

Maximum roll distance(mm) | 10mm |

Single feed | 5-10KG |

Power | 4KW |

Rotation Speed of Front Roll(rpm) | 19r/min |

Roll speed pattern | Constant speed (adjustable speed/double adjustable speed) |

Bearing situation | Insert bearing |

Reducer casing | planet-gear speed reducer |

Voltage | 380V |

Weight | ~750KG |

Dimension(L*W*H) | 1500*900*1350mm |

Key Features of a Two Roll Mill Machine

Adjustable Roller Gap: The gap between the two rollers can be easily adjusted, which helps control the thickness of the rubber sheet or mix. This feature is critical for ensuring consistent results and meeting the specific requirements of different applications.

Roller Material: Rollers are typically made of high-quality steel or alloy to withstand the pressure and wear during operation. Some mills come with hard chrome or ceramic coating to increase durability and reduce friction.

Cooling System: Two Roll Rubber Mill Machines are often equipped with a cooling system to prevent overheating during high-speed operation. The rollers may be cooled by water, oil, or air circulation to maintain optimal operating temperatures.

Advanced Control Panel: Modern Industrial Two Roll Mill Machines come with automated control systems that allow precise adjustments of speed, temperature, and pressure. This enhances production efficiency and reduces human error.

Safety Features: High-end models include safety guards, emergency shut-off switches, and overload protection to ensure operator safety and minimize equipment downtime.

Essential details | |

Model | YX-GK190 |

Roller speed ratio | 19r/min |

Roller diameter | 190mm |

Roller deceleration | fixed speed (speed regulation/double speed regulation can be ordered) |

Roller length | 600mm |

Bearing Situation | Outer Spherical Bearings |

Maximum roller distance | 10mm |

Gearbox | worm gear reducer |

Feeding at one time | 5-20KG |

Power supply | 380V |

Main motor power | 5.5KW |

Weight | 800KG |

Front roller line speed | 19r/min |

Machine size | 1600*900*1350mm |

Applications of Double Roll Rubber Mills

Double Roll Rubber Mills are used in a variety of applications across a wide range of industries. Here are some common uses:

Rubber Compounding: The primary application for double roll rubber mill suppliers is to mix different rubber compounds, including base rubber, fillers, and additives. This is essential for manufacturing customized rubber products that meet specific performance requirements.

Rubber Sheet Production: Double roll rubber mills can produce rubber sheets of varying thicknesses. These rubber sheets are then cut into different shapes and used to manufacture products such as seals, gaskets, and automotive parts.

Recycling: Double roll rubber mills can also be used for rubber recycling, specifically recycling scrap rubber for reuse in manufacturing. This process helps reduce waste and improves the overall sustainability of rubber production.

Tire Manufacturing: Double roll rubber mills play a vital role in the production of rubber used in tire manufacturing. The mill ensures that the rubber compounds are mixed to the correct consistency, which directly affects the quality and performance of the tire.

Rubber Coating: Mills are used to coat rubber onto fabrics and other materials, often in industrial applications, ensuring that the coating is uniform and durable.

Benefits of Purchasing from YUNXIN – A Trusted Two Roll Mill Machine Manufacturer

As a trusted Two Roll Mill Machine Manufacturer, YUNXIN offers several benefits for businesses seeking high-quality rubber processing equipment:

High-Quality Construction: YUNXIN machines are built with precision engineering, ensuring robust performance and longevity even under demanding conditions. The Industrial Two Roll Mill Machine is designed for heavy-duty operations, making it ideal for large-scale manufacturing.

Customization Options: Depending on your specific needs, YUNXIN provides customizable solutions for roller size, cooling systems, and control panel configurations. This flexibility allows you to tailor the machine to your exact requirements.

Competitive Pricing: YUNXIN offers the Two Roll Mill at Best Price in China, ensuring that you receive top-quality equipment at a price point that suits your budget. This value proposition makes it an attractive option for businesses of all sizes.

After-Sales Support: As a leading Two Roll Mill Equipment Supplier, YUNXIN offers comprehensive after-sales support, including installation, training, and maintenance services. Their dedicated customer service team ensures that your equipment remains in peak condition.

Global Shipping: YUNXIN’s commitment to providing high-quality equipment extends globally, with efficient shipping and timely delivery to countries around the world.

How to Choose the Right Two Roll Mill Machine Supplier

When selecting a Two Roll Mill Machine Supplier, consider the following factors:

Quality and Durability: Look for a supplier that offers robust, high-quality machines designed to last for years. YUNXIN’s machines are made from top-grade materials and built to withstand the rigors of industrial production.

Customization and Flexibility: If you need a Two Roll Rubber Mill Machine with specific features or modifications, choose a supplier that can provide tailored solutions. YUNXIN offers machines that can be adapted to suit your production needs.

Cost-Effectiveness: Ensure that the supplier provides competitive pricing without compromising on quality. With Two Roll Mill at Best Price in China, YUNXIN ensures excellent value for money.

After-Sales Service: A reliable supplier should offer excellent after-sales service, including installation, technical support, and spare parts availability.

FAQ

1. What is the primary use of a Two Roll Rubber Mill Machine?

A Two Roll Rubber Mill is primarily used for mixing rubber compounds, refining materials, and producing rubber sheets. It is essential in industries like tire manufacturing, automotive, and rubber product development.

2. How do I maintain my Two Roll Mill Machine?

Regular maintenance includes cleaning the machine after each use, checking the rollers for wear, ensuring the cooling system is functioning, and performing periodic inspections to detect any potential issues.

3. Can the Two Roll Mill Machine handle different types of rubber?

Yes, the Two Roll Rubber Mill Machine is versatile and can process various types of rubber, including natural and synthetic rubbers, as well as specialized compounds with fillers and additives.

4. What is the typical lifespan of a Two Roll Rubber Mill Machine?

The lifespan of a Two Roll Rubber Mill Machine depends on maintenance and usage. With proper care, these machines can last many years, providing reliable performance for your production needs.

5. Is the Two Roll Mill Machine customizable?

Yes, YUNXIN offers customization options for the Two Roll Rubber Mill Machine, including different roller sizes, cooling systems, and control panel configurations to meet specific production requirements.

6. What are the advantages of buying a Two Roll Mill from China? China is known for offering high-quality machinery at competitive prices. YUNXIN provides Two Roll Mill at Best Price in China, ensuring excellent value for businesses seeking cost-effective solutions without compromising quality.