Rubber Forming Machines find applications across a diverse range of industries where rubber materials need to be shaped, molded, or formed into specific products. The versatility of rubber forming processes allows for the creation of various components with different shapes, sizes, and properties.The choice of a Rubber Forming Machine depends on the specific forming process, the complexity of the product, the production volume, and other factors related to the desired end product.

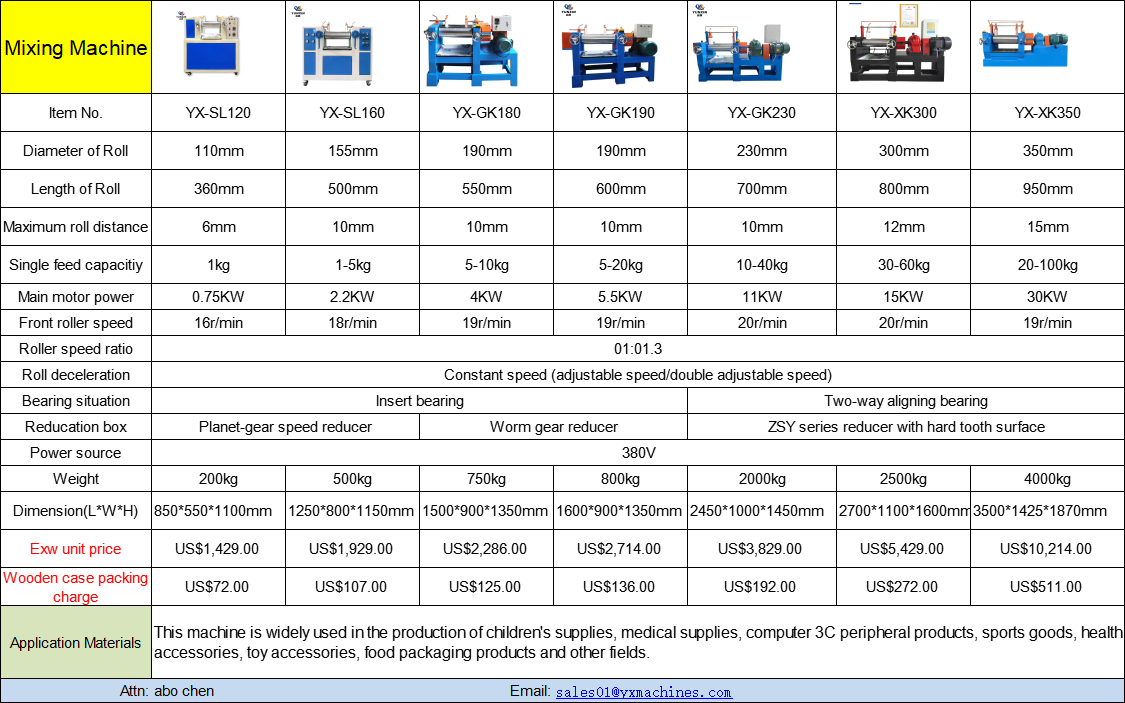

Model | YX-GK180 |

Diameter of Roll(mm) | 190mm |

Length of Roll(mm) | 550mm |

Maximum roll distance(mm) | 10mm |

Single feed | 5-10KG |

Power | 4KW |

Rotation Speed of Front Roll(rpm) | 19r/min |

Roll speed pattern | Constant speed (adjustable speed/double adjustable speed) |

Bearing situation | Insert bearing |

Reducer casing | planet-gear speed reducer |

Voltage | 380V |

Weight | ~750KG |

Dimension(L*W*H) | 1500*900*1350mm |

Essential details | |

Model | YX-GK190 |

Roller speed ratio | 19r/min |

Roller diameter | 190mm |

Roller deceleration | fixed speed (speed regulation/double speed regulation can be ordered) |

Roller length | 600mm |

Bearing Situation | Outer Spherical Bearings |

Maximum roller distance | 10mm |

Gearbox | worm gear reducer |

Feeding at one time | 5-20KG |

Power supply | 380V |

Main motor power | 5.5KW |

Weight | 800KG |

Front roller line speed | 19r/min |

Machine size | 1600*900*1350mm |

Features of Rubber Forming Machine

Precision molding: The rubber molding machine has high-precision molding capabilities and can accurately mold the rubber material into the required shape.

Versatility: Can adapt to different types and thicknesses of rubber materials to meet the molding needs of various shapes and sizes.

High degree of automation: equipped with an automated control system, easy to operate, high production efficiency, and reduced manual intervention.

Strong stability: The equipment operates stably, the quality of molded products is reliable, and production continuity and stability are ensured.

Energy saving and environmental protection: Using advanced energy saving technology, it can effectively reduce energy consumption and meet environmental protection requirements.

High reliability: The equipment structure is sturdy and durable, with long service life and low maintenance cost.

Advantages of Rubber Forming Machine

Efficient production: high degree of automation, greatly improving production efficiency and saving labor costs.

Flexibility: Parameters can be adjusted according to different molding requirements, and it is suitable for the production of a variety of rubber products.

High precision: high molding precision, stable and reliable finished product quality, and reduced defective products.

Cost savings: The production process is automated, reducing labor and time costs and improving production efficiency.

Strong adaptability: applicable to various rubber materials of different hardness, thickness and shape.

Application areas

Automobile manufacturing: Used to produce automobile rubber products such as automobile tires, seals, and rubber pipe fittings.

Industrial manufacturing: Suitable for the production of industrial rubber products such as industrial seals, pipe fittings, rubber vibration sound-absorbing parts, etc.

Electronic and electrical appliances: used in the production of electronic seals, cable joints, rubber keyboards and other electronic and electrical rubber products.

Construction engineering: used to produce construction engineering rubber products such as building waterproofing materials, sealing strips, rubber gaskets, etc.

Medical devices: Suitable for the production of medical silicone products, medical seals, artificial joints and other medical device rubber products.

Daily necessities manufacturing: used to produce daily necessities rubber products such as rubber sealing rings, rubber pipe fittings, rubber gaskets, etc.

Aerospace: Suitable for the production of rubber seals, vibration absorbers, rubber hoses, etc. in the aerospace field.

Sports equipment: used to produce sports equipment rubber products, such as sports venue plastics, fitness equipment rubber accessories, etc.

Rubber Forming Machine plays an important role in the production of rubber products in many industries due to its high efficiency, accuracy and flexibility.

What Is A Rubber Forming Machine?

A rubber forming machine is a specialized industrial equipment designed for shaping and molding rubber materials into various products. It utilizes heat, pressure, and molds to transform raw rubber compounds into finished items such as gaskets, seals, tires, and more. These machines are essential in the rubber manufacturing industry for producing high-quality, precision components.

How Does A Rubber Forming Machine Work?

A rubber forming machine operates by heating rubber material until it becomes pliable, then placing it into a mold cavity. Pressure is applied to the material, forcing it to take the shape of the mold. After cooling, the rubber retains its new shape, making it suitable for a wide range of applications. This process ensures uniformity and consistency in rubber product production.

What Are The Advantages Of Using Rubber Forming Machines?

Rubber forming machines offer several advantages, including increased production efficiency, reduced material wastage, and enhanced product quality. They enable manufacturers to create complex shapes with precision and consistency, making them ideal for industries where tight tolerances and quality control are crucial.

Are There Different Types Of Rubber Forming Machines?

Yes, there are various types of rubber forming machines, including hydraulic presses, compression molding machines, transfer molding machines, and injection molding machines. Each type has its unique features and applications, catering to the diverse needs of the rubber industry.

What Safety Measures Should Be Taken When Operating A Rubber Forming Machine?

Safety is paramount when working with rubber forming machines. Operators must receive proper training, wear appropriate protective gear, and follow established safety protocols. Regular machine maintenance and inspection are also essential to prevent accidents and ensure the equipment's longevity.

In summary, a rubber forming machine is a vital tool in the rubber manufacturing industry, allowing for the efficient production of high-quality rubber products. Understanding how these machines work, their advantages, and the importance of safety measures is crucial for anyone involved in rubber processing.