Rubber Mixing Mill Machine suitable for plastic industry polymer material mixing and processing such as, PVC, color master batch. Making the raw material and compound mixing, and achieve the required color and quality. The machine adopts special heated mold, roll surface temperature uniformity, never take off a layer, sample thickness can be mixed, the machine safety protection device, convenience to use.

Product parameters

Model | YX-SL120 |

Diameter of Roll(mm) | 110mm |

Length of Roll(mm) | 360mm |

Maximum roll distance(mm) | 6mm |

Single feed | Within 1KG |

Power | 0.75KW |

Rotation Speed of Front Roll(rpm) | 16r/min |

Roll speed pattern | Constant speed (adjustable speed/double adjustable speed) |

Bearing situation | Insert bearing |

Reducer casing | planet-gear speed reducer |

Voltage | 380V |

Weight | 200KG |

Dimension(L*W*H) | 850*550*1100mm |

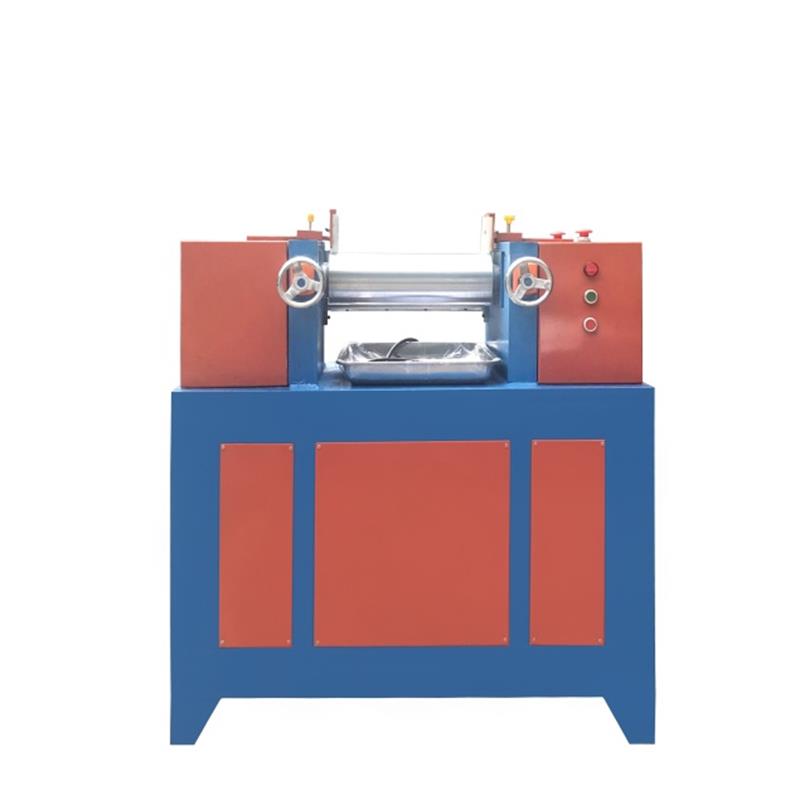

Product Image

Product Details

Essential details | |||

Diameter of Roll(mm) | 120 mm, 110mm | Warranty | 1 Year |

Rotation Speed of Front Roll(rpm) | 1 - 16 rpm, 16r/min | Key Selling Points | Long Service Life |

Length of Roll(mm) | 360 mm, 360mm | Power (kW) | 0.75 |

Roll Ratio(Front/Back) | 01:01.3 | Weight (KG) | 200 KG |

Video outgoing-inspection | Provided | Applicable Industries | Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory |

Machinery Test Report | Provided | Showroom Location | None |

Warranty of core components | 3 years | Model | YX-SL120 |

Core Components | Motor | Maximum roll distance(mm) | 6mm |

Cooling Mode | water cooling | Single feed | Within 1KG |

Condition | New | Power | 0.75KW |

Place of Origin | Guangdong, China | Roll speed pattern | Constant speed (adjustable speed/double adjustable speed) |

Voltage | A.C.380V 50HZ | Bearing situation | Insert bearing |

Dimension(L*W*H) | 850*550*1100(mm) | Reducer casing | planet-gear speed reducer |

Year | 2020 | ||

Feature:

1. Construction of mill rolls: drilled roll, bored roll, grooved roll

2. We can design speed ratio as per customers' formula and processing requirements.

3. Frame, frame cap and base are welded and treated by annealing for stress relieving.

4. Rolls material is chilled cast alloy iron which hardness is reach to 70HB.

5. Brake and emergency stop device can ensure the safety of personnel and equipment.

6. Auto feeding oil or grease lubrication, it is easy to maintain and protect machine.

7. Human nature designed controlling system ensure labor safety.

8. Methods of adjusting roll nip: manual or electric

Intelligent control panel and PLC control system:

1. Real-time data record and export of kneading time, temperature (mixing chamber and front/rear rotors), ram pressure, current,

torque and recipe code.

2. The control system can be set up to 20 mixing steps, save 20 recipe spaces.

3. The control system is capable of remote import of the process recipe and data monitoring, communicating with MES via Ethernet

communication interface.

4. An Ethernet communication interface and 20% of the control points are reserved. Touch screen is provided.

Advantages

Efficient mixing

Rubber Mixing Mill Machine can effectively mix all kinds of rubber raw materials, additives, fillers, etc., to ensure that the physical and chemical properties of rubber products meet the preset standards. Its powerful shear force and mixing force can quickly and evenly disperse the various components to improve production efficiency.

Flexible operation

Rubber mixing machine usually has a variety of adjustable parameters, such as roller pitch, speed, temperature, etc., to adapt to the needs of different materials and processes. Operators can flexibly adjust according to the actual situation to get the best mixing effect.

Strong processing capacity

The rubber mixing machine is suitable for processing rubber materials of various viscosities, including high viscosity, low viscosity and rubber containing a large number of fillers. Its strong processing capacity makes it an indispensable equipment in the rubber industry.

High degree of automation

Modern rubber mixers are usually equipped with advanced control systems, such as PLC (Programmable Logic Controller) and touch-screen operator interface, which makes the operation of the equipment easier and more intuitive. At the same time, the automation control system is also able to achieve self-diagnosis of faults and remote monitoring, improving the reliability and safety of the equipment.

Energy saving and environmental protection

Rubber mixing machine focuses on energy saving and environmental protection in its design, reducing energy consumption and exhaust emissions through optimising the structure and reducing energy consumption. Meanwhile, the equipment usually adopts closed design to reduce dust and noise pollution.

Easy to maintain

The structure of rubber mixing machine is reasonably designed, easy to maintain and repair. Key components such as rollers, bearings, etc. are usually made of high-quality materials, with high wear resistance and service life. In addition, the equipment is usually equipped with a perfect lubrication system and cooling system to ensure the stability and reliability of the equipment in the long run.

Wide range of application

Rubber mixer is not only suitable for the production of rubber products, but also can be used for mixing and processing of materials in plastic, chemical and other industries. Its wide range of application makes it become one of the indispensable equipment in a variety of industries.

Application Fields:

Rubber products industry

Rubber mixing machine is an indispensable equipment in the production line of rubber products. It can mix various rubber raw materials, additives, fillers, etc. to prepare rubber mixes that meet the process requirements. These mixing rubber can then be used to manufacture tyres, rubber pipes, rubber belts, rubber sheets and other rubber products.

Tyre Manufacturing

In the tyre manufacturing process, rubber mixing machines are used to mix rubber raw materials, carbon black, plasticisers, antioxidants and other additives to prepare the required compound for tyres. This kind of rubber mixing has excellent physical and chemical properties, which can meet the requirements of tyres in high-speed driving, heavy load and complex environmental conditions.

Rubber hose, rubber belt and other manufacturing industries

These industries also need to use rubber mixing machine to prepare rubber mixing. The quality of the rubber mixer directly affects the performance and service life of the rubber hose, rubber belt and other products.

Plastics and chemical industry

Although rubber mixers are mainly used in the production of rubber products, they can also be used as mixing and moulding equipment in the production process of certain plastics and chemical products. For example, in the fields of plastic modification and pigment preparation, rubber mixing machines can play a similar role.

Rubber Mixing Mill Machine has a wide range of applications in the rubber products industry, tyre manufacturing, rubber hose, rubber belt and other manufacturing industries as well as in the plastics and chemical industries.

FAQ

1.Do you have customers of our country before?

Now our testing machines have been sold to more than 80 countries, like USA, Canada, Russia,UK, Italy, Germany, European , India, Pakistan, Philippine, Singapore, Malaysia,Thailand , Vietnam, Korea,Saudi Arabia,Brazil...and so on.

2.How about your warranty?

Generally,our warranty is one years. Within the warranty period, we can offer technique support and part parts change, necessarily, our engineers may go to your place for better service.

3.How about the packing for machine, is it safely protected during transportation?

Our machine is packed by standard export wooden box, it won’t be damaged. We’ve delivered many testing machines abroad by sea or by air without damage.

4.What is the order process?

Inquiry - quotation - communication - order confirming - deposit payment - production - testing and debugging - balance payment - packing - delivery - customer receiving - after service.

5.How to install and use the product?

The product is shipped with an operating instructions and video of English version.

Product Q&A

The main components of Rubber Mixing Mill Machine include a mixing chamber, rotors, and auxiliary systems for temperature control, feeding, and discharge. The interaction of these elements ensures thorough mixing and dispersion of rubber compounds.

Rubber Mixing Mill Machine enhances manufacturing efficiency by automating the mixing process. Its ability to handle large volumes of material with precision and speed reduces manual labor requirements and accelerates production timelines.

Yes, Rubber Mixing Mill Machine is often customizable to meet specific production requirements. Manufacturers can tailor the equipment's capacity, mixing intensity, and additional features to align with the characteristics of the rubber compounds and the desired final product.

Temperature control is crucial in Rubber Mixing Mill Machine to manage the viscosity of rubber compounds. Maintaining the optimal temperature ensures efficient mixing and prevents premature vulcanization, contributing to the overall quality of the rubber product.

Rubber Mixing Mill Machine contributes to environmental sustainability by minimizing material wastage and energy consumption. Precise mixing reduces the need for rework, and efficient machinery design ensures resource-efficient production processes.

Safety measures for Rubber Mixing Mill Machine include the incorporation of protective guards, emergency stop features, and comprehensive operator training. Adhering to these measures ensures a secure working environment and minimizes the risk of accidents.

Yes, Rubber Mixing Mill Machine is designed to handle specialty rubber formulations, including those with unique additives, fillers, or reinforcement materials. This adaptability makes it suitable for industries with diverse and specialized rubber requirements.

In the tire manufacturing industry, Rubber Mixing Mill Machine ensures the consistent quality of rubber compounds used in tire production. This consistency directly impacts tire performance, durability, and safety.

Routine maintenance practices, such as cleaning, lubrication, and inspection of wear parts, are essential for ensuring the longevity and optimal performance of Rubber Mixing Mill Machine. Regular upkeep minimizes downtime and extends the lifespan of the machinery.