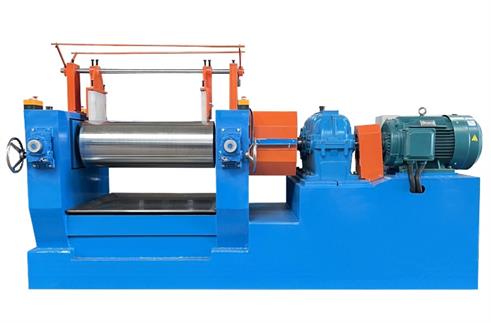

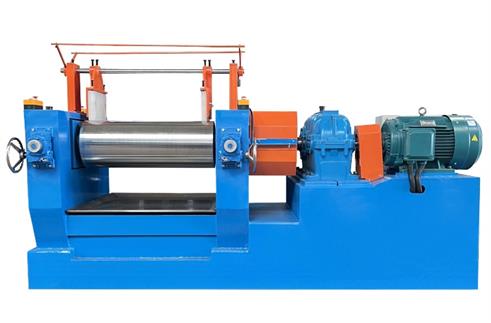

As a leading rubber mixer manufacturer, we are committed to providing customers with high-performance and efficient rubber mixing equipment.

Our rubber mixers are suitable for mixing and processing various rubber and elastomer materials, and are widely used in tires, rubber products, seals, soles and other industries, providing customers with the best mixing solutions.

Product Parameters

Model | YX-XK350 |

Diameter of Roll(mm) | 300mm |

Length of Roll(mm) | 800mm |

Maximum roll distance(mm) | 12mm |

Single feed | 20-60KG |

Power | 15KW |

Rotation Speed of Front Roll(rpm) | 20r/min |

Roll speed pattern | Constant speed (adjustable speed/double adjustable speed) |

Bearing situation | Insert bearing |

Reducer casing | planet-gear speed reducer |

Voltage | 380V |

Weight | ~2500KG |

Dimension(L*W*H) | 2700*1100*1600mm |

Product Features

Efficient mixing: Equipped with advanced mixing rollers to ensure uniform mixing of materials and improve product consistency and quality.

Powerful power: The powerful 15KW power system can meet the needs of high-intensity mixing and adapt to the mixing process of different types of rubber materials.

Precise control: The front roller speed is 20r/min, and the roller speed mode can be selected as constant speed, adjustable speed and dual speed regulation to meet different process requirements and achieve precise mixing.

Durable structure: Embedded bearings and planetary gear reducers are used to ensure the durability and stability of the equipment and extend its service life.

Flexible operation: The maximum roller spacing is 12mm, and the single feed amount can reach 20-60KG, which can meet the production needs of different batches.

Compact design: The equipment size is 2700x1100x1600mm, with a small footprint, suitable for various production environments.

Product Details

Essential details | |||

Diameter of Roll(mm) | 350 mm, 350mm | Year | 2020 |

Rotation Speed of Front Roll(rpm) | 1 - 19 rpm, 19r/min | Warranty | 1 Year |

Length of Roll(mm) | 950 mm, 950mm | Key Selling Points | Long Service Life |

Roll Ratio(Front/Back) | 1:1.25 | Power (kW) | 30 |

Video outgoing-inspection | Provided | Weight (KG) | 4000 KG |

Machinery Test Report | Provided | Applicable Industries | Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory |

Warranty of core components | 1 Year | Showroom Location | None |

Core Components | Motor | Model | YX-XK350 |

Cooling Mode | water cooling | Maximum roll distance(mm) | 15mm |

Condition | New | Single feed | 20KG-100KG |

Place of Origin | Guangdong, China | Power | 30KW |

Voltage | A.C.380V 50HZ | Roll speed pattern | Constant speed (adjustable speed/double adjustable speed) |

Dimension(L*W*H) | 3500*1425*1870mm | Bearing situation | Insert bearing |

Advantages and Features of YX-XK350 Rubber Mixing Machine

Advantages:

High Mixing Efficiency:The front roll rotates at 19 rpm, coupled with a 1:1.25 roll speed ratio, ensuring uniform distribution of rubber materials and enhancing production efficiency.

Durability and Stability:Equipped with insert bearings and a planetary gear speed reducer, the machine is robust and wear-resistant, capable of stable operation for extended periods, thereby reducing maintenance costs.

Precision Control:Offers constant speed, adjustable speed, and double adjustable speed modes for the rolls, allowing precise control according to different materials and processing requirements to ensure consistent mixing quality.

Video Outgoing Inspection and Machinery Test Report:

Each unit undergoes rigorous video outgoing inspection and mechanical testing to ensure compliance with manufacturing standards, enhancing customer confidence.

Suitable for various industries including tire manufacturing, rubber product production, seal manufacturing, and shoe sole production, meeting diverse production needs.

Features:

Water Cooling System: Efficient water cooling system effectively controls equipment temperature, ensuring stable operation over long periods.

New Condition: All machines are in brand-new condition, ensuring stable performance and long service life.

High Power Output: Equipped with a 30 kW powerful motor system, capable of handling large volumes of rubber materials to improve production efficiency.

Compact Design: Compact structure with a small footprint, suitable for various production workshop layouts.

The YX-XK350 Rubber Mixing Machine, with its advanced technology and reliable performance, plays a crucial role in the rubber processing industry, making it an ideal choice for enhancing production efficiency and product quality.

FAQ

What is a Rubber Mixing Machine used for?

A Rubber Mixing Machine is used to blend rubber and elastomer materials to achieve uniform consistency and desired properties for various industrial applications such as tire manufacturing, rubber products, seals, and shoe soles.

What are the key features of the Rubber Mixing Machine?

The YX-XK350 features a 350 mm diameter roll, operates at 19 rpm, has a 950 mm roll length, and offers a 1:1.25 roll speed ratio. It includes a water cooling system, is new and from Guangdong, China, operates on A.C. 380V 50HZ, and measures 3500x1425x1870mm in size.

What industries can benefit from the Rubber Mixing Machine?

Industries such as manufacturing plants, machinery repair shops, and food and beverage factories can benefit from the YX-XK350 Rubber Mixing Machine due to its versatile applications.

How is the Rubber Mixing Machine cooled?

The YX-XK350 utilizes a water cooling system to maintain optimal operating temperatures during production.

What warranty is provided with the Rubber Mixing Machine?

The YX-XK350 comes with a 1-year warranty on its core components, ensuring reliability and peace of mind for the buyer.

Where is the Rubber Mixing Machine manufactured?

The YX-XK350 Rubber Mixing Machine is manufactured in Guangdong, China.

What is the power output of the Rubber Mixing Machine?

The YX-XK350 is equipped with a 30 kW motor, providing substantial power for efficient rubber mixing operations.

How does the Rubber Mixing Machine ensure quality control?

Each YX-XK350 machine undergoes video outgoing inspection and has a machinery test report provided, ensuring that it meets rigorous quality standards before delivery.

What are the dimensions and weight of the Rubber Mixing Machine?

The measures 3500x1425x1870mm (LWH) and weighs 4000 KG, making it suitable for various production environments with its compact yet robust design.