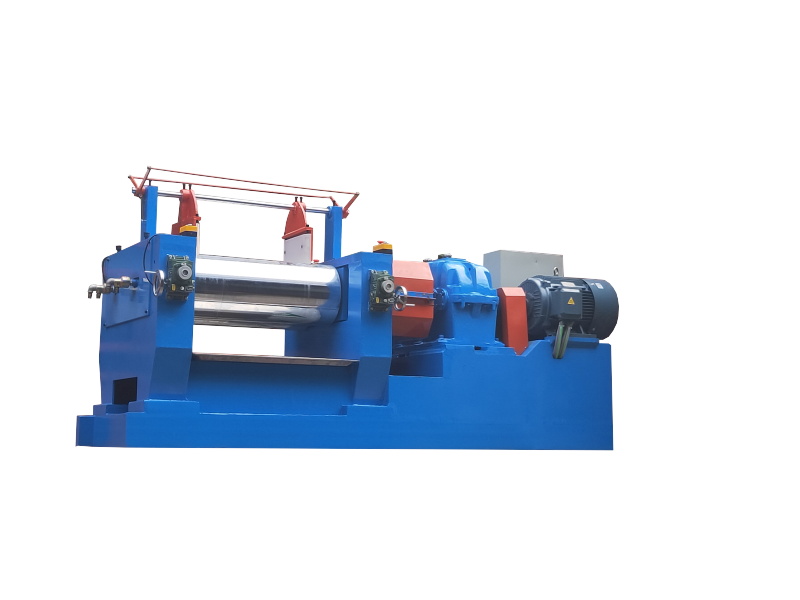

Rubber mixer is an important equipment in rubber processing industry, widely used in mixing, refining and blending natural rubber, synthetic rubber and rubber compound to ensure the uniformity and quality of rubber materials. This machine is usually used in rubber manufacturing plants, tire production and other related industries.

Model | YX-XK350 |

Diameter of Roll(mm) | 300mm |

Length of Roll(mm) | 800mm |

Maximum roll distance(mm) | 12mm |

Single feed | 20-60KG |

Power | 15KW |

Rotation Speed of Front Roll(rpm) | 20r/min |

Roll speed pattern | Constant speed (adjustable speed/double adjustable speed) |

Bearing situation | Insert bearing |

Reducer casing | planet-gear speed reducer |

Voltage | 380V |

Weight | ~2500KG |

Dimension(L*W*H) | 2700*1100*1600mm |

Working Principle

The YX-XK350 rubber mixer works by the relative rotation of two large rollers. The two rollers rotate in opposite directions and at different speeds, forming shear forces, which effectively mix the rubber raw materials with additives (such as carbon black, oils and chemicals, etc.). The raw materials are fed between the rollers, and the viscosity of the materials gradually decreases during multiple passes, ensuring uniform mixing. The diameter and length of the rollers (300mm and 800mm) determine the amount of material processed each time. The machine is equipped with a planetary gear reducer to accurately control the speed of the rollers.

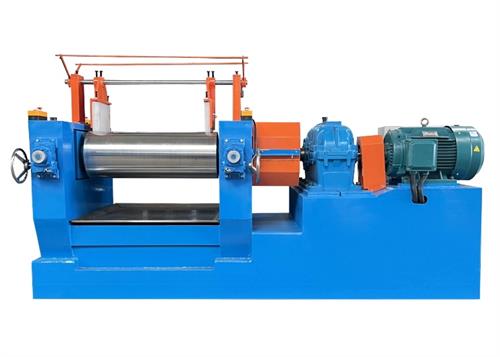

Essential details | |||

Diameter of Roll(mm) | 350 mm, 350mm | Year | 2020 |

Rotation Speed of Front Roll(rpm) | 1 - 19 rpm, 19r/min | Warranty | 1 Year |

Length of Roll(mm) | 950 mm, 950mm | Key Selling Points | Long Service Life |

Roll Ratio(Front/Back) | 1:1.25 | Power (kW) | 30 |

Video outgoing-inspection | Provided | Weight (KG) | 4000 KG |

Machinery Test Report | Provided | Applicable Industries | Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory |

Warranty of core components | 1 Year | Showroom Location | None |

Core Components | Motor | Model | YX-XK350 |

Cooling Mode | water cooling | Maximum roll distance(mm) | 15mm |

Condition | New | Single feed | 20KG-100KG |

Place of Origin | Guangdong, China | Power | 30KW |

Voltage | A.C.380V 50HZ | Roll speed pattern | Constant speed (adjustable speed/double adjustable speed) |

Dimension(L*W*H) | 3500*1425*1870mm | Bearing situation | Insert bearing |

Function

The main functions of the rubber mixer are:

Mixing rubber compound: ensuring that all ingredients (such as natural rubber, synthetic rubber, accelerators, oil, etc.) are thoroughly mixed to achieve a uniform material.

Refining rubber: improving the viscosity and quality of rubber and improving uniformity through multiple processing.

Raw material preparation: providing blended rubber compound for further processing (such as vulcanization, extrusion, etc.).

Features

Roller specifications: The roller diameter is 300mm and the length is 800mm, which is suitable for medium and large-scale mixing operations.

Maximum roller spacing 12mm: This function allows the gap between the rollers to be adjusted to control the thickness of the mixed material.

Single feed amount 20-60kg: suitable for medium to large-scale production, the single feed amount is flexible and can meet the needs of different batches.

Planetary gear reducer: The reducer provides precise roller speed control to ensure uniformity and efficiency of the mixing process.

Power and speed control: The machine is equipped with a 15KW motor, a front roller speed of 20rpm, and an adjustable roller speed to adapt to different mixing needs.

Insert bearings: Durable insert bearings are used to reduce friction and extend the service life of the equipment.

Adjustable speed options: The machine can provide constant speed, adjustable speed or dual speed adjustment functions, with greater operational flexibility.

Heavy-duty structure: The machine weighs about 2500KG, has good stability, and low vibration during operation, ensuring the smoothness of the mixing process.

Advantages

Consistency: Ensures uniform mixing of rubber and improves the quality of the final product.

Efficiency: The adjustable speed and power control system optimizes mixing time and energy efficiency, improving production efficiency.

Durability: High-quality bearing and reducer structure increase the durability of the equipment and reduce maintenance requirements.

Versatility: It can handle a variety of rubber formulas and adapt to different types of rubber processing.

Automation capability: Some versions are also equipped with an enhanced control system to achieve automated operation, improve accuracy and reduce labor costs.

Scope of use

The YX-XK350 rubber mixer is widely used in industries that require rubber raw material blending. Common application areas include:

Tire manufacturing: used to mix rubber compounds in tire production.

Rubber product production: including the production of rubber products such as rubber tubes, belts, seals, gaskets, etc.

Rubber recycling: widely used in the treatment and refining of recycled rubber, processing recycled rubber into new raw materials.

Synthetic rubber processing: suitable for mixing various synthetic rubbers, such as butyl rubber and nitrile rubber, which are widely used in the automotive and industrial fields.

Chemical and plastic industries: The machine can also be used to mix rubber or plastic compounds with other chemical components to improve the performance of the materials.

In short, the YX-XK350 rubber mixer is a powerful and versatile rubber processing equipment with high-quality mixing capacity, energy efficiency and durability, suitable for large-scale and small-scale production needs.