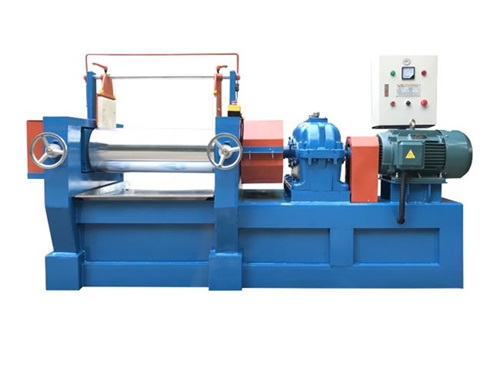

Rubber Mixing Mill is a key rubber processing equipment produced by professional manufacturers. It is mainly used to mix rubber with various additives (such as fillers and dyes) to prepare rubber compound.

This equipment is widely used in rubber products industry, such as rubber products production, tire manufacturing and plastic industry. Manufacturers optimize equipment design and process to ensure that it provides efficient and reliable performance in the mixing process to meet customers' needs for rubber mixing quality and efficiency.

Model | XY-XK300 |

Diameter of Roll(mm) | 300mm |

Length of Roll(mm) | 800mm |

Maximum roll distance(mm) | 12mm |

Single feed | 20-60KG |

Power | 15KW |

Rotation Speed of Front Roll(rpm) | 20r/min |

Roll speed pattern | Constant speed (adjustable speed/double adjustable speed) |

Bearing situation | Insert bearing |

Reducer casing | planet-gear speed reducer |

Voltage | 380V |

Weight | ~2500KG |

Dimension(L*W*H) | 2700*1100*1600mm |

Rubber Mixing Mills are primarily used for:

Rubber Compounding: Efficiently blends raw rubber with additives such as fillers, plasticizers, and pigments to achieve uniformity and desired physical properties.

Batch Mixing: Prepares batches of rubber compounds for further processing into finished products.

Advantages

Precision Mixing: Ensures thorough and uniform blending of rubber compounds, critical for achieving consistent product quality.

Versatility: Suitable for processing a wide range of rubber materials, including natural rubber, synthetic rubber, and elastomers.

Operational Efficiency: Designed with features like adjustable speed control and robust gearing systems to optimize mixing efficiency and reduce processing time.

Quality Control: Facilitates stringent quality control measures by maintaining batch-to-batch consistency in rubber compound formulations.

Rubber Mixing Mills find application in diverse industries, including:

Automotive: Production of tires, belts, hoses, and seals where consistent material properties are crucial for performance and safety.

Industrial Manufacturing: Manufacturing of conveyor belts, gaskets, and molded rubber parts used in machinery and equipment.

Footwear: Mixing rubber compounds for shoe soles and components, ensuring durability and comfort.

Products manufactured using rubber compounds processed in Mixing Mills include:

Tires: Essential components for vehicles, ensuring traction, durability, and safety on roads.

Industrial Seals and Gaskets: Provides sealing solutions for machinery and equipment, preventing leakage and enhancing operational efficiency.

Footwear Components: Rubber soles and components for shoes, offering comfort, traction, and durability.

Essential details | |||

Diameter of Roll(mm) | 300 mm, 300mm | Warranty | 1 Year |

Rotation Speed of Front Roll(rpm) | 1 - 20 rpm, 20r/min | Key Selling Points | Long Service Life |

Length of Roll(mm) | 800 mm, 800mm | Power (kW) | 15 |

Roll Ratio(Front/Back) | 1:1.25 | Weight (KG) | 2500 KG |

Video outgoing-inspection | Provided | Applicable Industries | Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory |

Machinery Test Report | Provided | Showroom Location | None |

Warranty of core components | 1 Year | Model | XY-XK300 |

Core Components | Motor | Maximum roll distance(mm) | 12mm |

Cooling Mode | water cooling | Single feed | 20KG-60KG |

Condition | New | Power | 15KW |

Place of Origin | Guangdong, China | Roll speed pattern | Constant speed (adjustable speed/double adjustable speed) |

Voltage | A.C.380V 50HZ | Bearing situation | Insert bearing |

Dimension(L*W*H) | 2700*1100*1600mm | Reducer casing | planet-gear speed reducer |

Year | 2020 | ||

What is a Mixing Mill Machine?

A Mixing Mill Machine is a specialized industrial equipment used in rubber and plastic processing. It consists of two counter-rotating rolls that work together to mix and knead rubber or plastic compounds. This machine plays a crucial role in various manufacturing processes, including tire production and plastic molding.

How does a Mixing Mill Machine work?

A Mixing Mill Machine operates by feeding the rubber or plastic material between two rolls, which then compress and shear the material, mixing it thoroughly. This process helps in achieving uniformity in compound composition and also facilitates the removal of impurities and air bubbles from the material.

What are the advantages of using a Mixing Mill Machine?

Using a Mixing Mill Machine offers several advantages. It ensures consistent mixing of materials, improves material quality, and enhances the physical properties of rubber or plastic compounds. Additionally, it can be used for batch processing and is essential in achieving precise formulations.

Can Mixing Mill Machines be used for other materials besides rubber and plastic?

While Mixing Mill Machines are primarily designed for rubber and plastic processing, they can also be used for mixing and blending various other materials, such as ceramics and certain chemicals. However, their primary application remains in the rubber and plastic industries.

What safety measures should be taken when operating a Mixing Mill Machine?

Operating a Mixing Mill Machine requires adherence to strict safety protocols. This includes using appropriate personal protective equipment, ensuring machine guards are in place, and following proper lockout/tagout procedures. Adequate training and supervision are essential to prevent accidents.

How to maintain and care for a Mixing Mill Machine?

Maintaining a Mixing Mill Machine is vital for its longevity and efficient operation. Regular lubrication of moving parts, inspection for wear and tear, and cleaning to remove accumulated debris are essential maintenance tasks. Following the manufacturer's maintenance guidelines is crucial.

What types of Mixing Mill Machines are available in the market?

The market offers a variety of Mixing Mill Machines, including open mill machines and closed mill machines. Open mill machines have exposed rolls and are commonly used for mixing and sheeting rubber. Closed mill machines have an enclosed mixing chamber, offering more control over the process and are used for specialized applications.

Are there any innovations in Mixing Mill Machine technology?

The field of Mixing Mill Machines has seen advancements in automation, process control, and digital monitoring in recent years. These innovations enhance precision and efficiency, making it easier to achieve consistent and high-quality rubber and plastic compounds. Keep an eye on the latest developments to stay competitive in the